Submitted by admin on

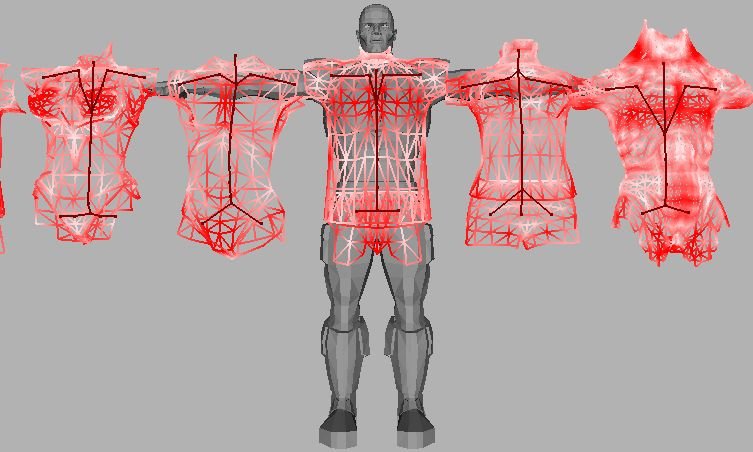

The user is presented with a ribbon of choices for the torso, which are colored according to their distance from the target mesh.

For all the power that computers have brought to the process of animation, it remains the human eye that’s the best judge of whether animated things moving in space look real.

“People intuitively know exactly what to draw to evoke realism,” says Don Fussell, professor of computer science. “Computers don’t have that luxury.”

What computers can do, however, is systematize the labor, liberating humans to focus their talents and energies where it’s needed most. That’s what Fussell and his doctoral student Christian Miller are doing with their new system Frankenrigs.

Using data from characters that have already been meticulously, laboriously animated by humans, Frankenrigs assembles a virtual warehouse of body parts. For each arm, leg, and torso in the warehouse there are precise measurements of how long the bones are, where the joints are, and where and how the artist attached the character’s outer skin (its “mesh”) to its inner skeleton (its “rig”). These last numbers, which are known as “skin weights,” are the most important in determining the way a character walks, run, jumps, falls, waves, punches and dances.

“Each bit of the mesh has a skin weight value saying which bone it’s atttached to,” says Miller. “It’s not one or zero, but a range. If it’s entirely attached to one bone, for instance, it moves rigidly with the bone. If it’s near a joint, and, say, 30 percent attached to one bone and 70 percent to the other, then when you move the skeleton it blends the motions.”

When an artist is beginning the process of animating a new character, which has a skin but no skeleton and no instructions for how the skin is attached to the skeleton, Frankenrigs automatically rummages through its database for old parts that are similar in shape to the new parts. Then, like a virtual Dr. Frankenstein, it stitches together a new body made up of the old parts, “skinning” it with a skin weight map composed of the skin weights of the old parts.

At a number of points in the process, the artist can step in to manually fine tune the character if the software makes a choice that doesn’t look right. If the software suggests an arm from its warehouse that looks too bulky, or that has an elbow at the wrong point along it, then the artist can cycle through the other arms in the warehouse for a better match. Or he can move the elbow joint a few jots to the left or right. If the skin weight map for a given joint doesn’t produce natural-looking deformations, then the artist can make use of a tool that Fussell and Miller call “the magic cylinder.” The user runs the cylinder over the problematic area, and more processing power is devoted to predicting the right skin weights.

When Frankenrigs has done everything it can to rig and skin a character so that it moves realistically, the artist can seamlessly plug the character back into Maya, which is the 3-D animation software that most industry animators us. Then one can do a final polish in Maya. The result, in the tests that Fussell and Miller have run, is an extraordinary amount of time saved.

What in the past might have taken artists weeks now takes hours.

Fussell and Miller aren’t the first to automate the task of skinning characters. In Maya, for instance, there’s already a tool that automatically rigs and skins meshes. But the automation is based purely on mathematical deductions, and the deformations it produces are very crude. As a consequence, animators are forced to spend a lot of time correcting the mistakes that the automation has made.

“The program in Maya will take a guess,” says Miller. “It can usually can get it right in the middle of arms or the middle of bones, but when it gets around joints it starts making big mistakes. Then the artist has to painstakingly modify the skin weights on each region of the mesh by using what’s called a skin weight brush, which looks like an actual paint brush. It’s all trial and error. They’ll paint a bit, flex the joint to see if it flexes the way they want it to. If it doesn’t, they’ll paint a little bit more. Flex it again. And so on and so on. It’s very tedious and time-consuming, and it’s not unusual for pros to spend weeks or even months getting the skinning right on a single character.”

With Frankenrigs, the automated rigging and skinning is so superior that even a novice animator can produce a near-professional quality animation in a short time. For a professional animator, although there will inevitably be some work with the skin-weight brush at the end of the process, it will be dramatically less work.

One of the more striking aspects of the success of Frankenrigs is that it’s been able to achieve such gains in efficiency and accuracy with a warehouse of parts that was salvaged from only 13 fully realized characters (which they got online from existing databases, or paid artists and students to create). If Frankenrigs is adopted by film and gaming studios, as Fussell and Miller hope it will be, the results should be even better. Such companies have massive collections of aliens, animals, monsters, soldiers and civilians they’ve already animated to move in exactly the way they want, and so their body parts warehouses should have limbs for nearly every occasion.

At the moment, Fussell and Miller are in talks with some Austin-based gaming companies about doing trial runs with the program. Even more promisingly, for the future of Frankenrigs, is the fact that the country’s premiere video game development master’s program, The Guildhall at SMU, has agreed to incorporate Frankenrigs into its toolbox. If the Guildhall students end up liking Frankenrigs, points out Fussell, they’ll want to keep using it when they graduate, and that means that they’ll bring it with them to places like Pixar, Dreamworks, ILM and the big gaming companies.

Closer to home, Fussell hopes that efforts like Frankenrigs will contribute to the eventual development of an undergraduate video gaming program at The University of Texas at Austin.

“For a long time, the advances in video gaming were coming almost entirely from industry,” he says. “That’s changing. A lot more is coming from academic computer science research, and. there are already centers of excellence for this. We’re a little bit behind, but I don’t think the opportunity has passed us by.”